Brush Aluminum Composite Panel

Brush Aluminum Composite Panel Specification

- Usage

- Commercial buildings signage cladding

- Feature

- Durable Lightweight Anti-corrosion

- Protective Film

- Yes

- Material

- Aluminum Composite Panel

- Dimension (L*W*H)

- 1220mm x 2440mm x 4mm

- Surface Treatment

- Brushed and anodized

- Coating Thickness

- 20 micron

- Panel Thickness

- 4mm

- Aluminum Thickness

- 0.5mm

- Tensile Strength

- 5-7 MPa

- Yield Strength

- 2-4 MPa

- Color

- Brushed Silver

- Application

- Interior and Exterior Decoration

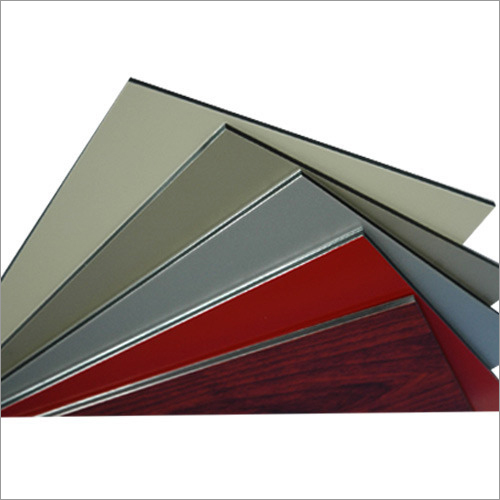

About Brush Aluminum Composite Panel

Brush Aluminum Composite Panel is well known for its various attributes such as sound insulation, surface flatness and fire resistant. This panel is permanently bonded to polyethylene core material. It is basically used to scrape out wires on the surface. Brush Aluminum Composite Panel is appropriate for ceiling decoration, display stands, purification and so on. It is made with a high quality of thermal comfort to make it more rigid sheet and corrosion resistant in nature.

Versatile Application

Brushed aluminum composite panels are designed for both interior and exterior architectural projects. Their dual-purpose nature makes them a popular solution for commercial building facades, signage, and decorative cladding. The brushed silver finish adds a modern touch to various environments, combining functionality with appealing aesthetics for any installation.

Superior Material Quality

Crafted with a 0.5mm aluminum exterior and a 4mm overall panel thickness, these panels deliver impressive tensile and yield strength. The 20-micron coating, along with the anodized, brushed surface, ensures long-term performance against corrosion and physical wear. A protective film is included to safeguard the finish during transport and installation.

FAQs of Brush Aluminum Composite Panel:

Q: How is the Brush Aluminum Composite Panel installed?

A: Installation of Brush Aluminum Composite Panels is straightforward and can be accomplished using common fixing systems for cladding and signage. The panels can be cut, drilled, and mounted onto various substrates with standard tools, making them suitable for both new constructions and renovation projects.Q: What are the main benefits of using this panel for exterior and interior decoration?

A: The panels offer a unique combination of durability, lightweight construction, and anti-corrosion properties. Their brushed silver surface provides a high-end appearance, and the anodized treatment boosts longevity. These benefits make them an excellent choice for lasting performance and aesthetics in commercial spaces.Q: When should you choose a brushed and anodized aluminum panel over other cladding options?

A: Choose brushed and anodized aluminum panels when you require an attractive, modern finish combined with superior weather resistance and strength. They are especially suitable for high-traffic areas or locations prone to moisture, ensuring the cladding stays protected and visually appealing.Q: Where can these panels be effectively used?

A: These panels are ideal for both interior and exterior applications, including commercial building facades, signage, showroom decorations, office partitions, and modern architectural projects throughout India and globally.Q: What is the process of protecting the panels during handling and installation?

A: Each panel is supplied with a protective film that shields the brushed surface from scratches and dust. This film should be kept on during transport and installation and only removed after the panel is secured in place.Q: How does the construction of this panel contribute to its lightweight and durability features?

A: The core structure combines a lightweight material sandwiched between 0.5mm thick aluminum sheets, resulting in a durable yet easy-to-handle panel. The engineered design ensures the product maintains structural strength while reducing overall weight, making it simple to install and transport.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Aluminium Composite Panels Category

3 mm PVDF Aluminum Composite Panel

Price 70 INR / Square Foot

Minimum Order Quantity : 160 Square Foots

Usage : Other, Curtain Wall, Facade, Exterior Cladding

Application : Exterior

Surface Treatment : PVDF Coated

Feature : Other, Weather Resistant, High Strength, Fire Retardant

White Aluminium Composite Panel

Price 62 INR / Square Foot

Minimum Order Quantity : 160 Square Foots

Usage : Other, Cladding, Facade, Signage, Wall Panel, Decoration

Application : Exterior

Surface Treatment : PVDF Coated

Feature : Other, Weather resistant, Anticorrosive, UV resistant

Mirror Aluminum Composite Panel

Price 85 INR / Square Foot

Minimum Order Quantity : 160 Square Foots

Usage : Other, Wall cladding, Interior decoration, Signage, False ceilings

Application : Interior

Surface Treatment : Mirror

Feature : Other, High gloss, Durable, Lightweight, Fire retardant, Weather resistance

Timber Walnut Aluminum Composite Panel

Price 120 INR / Square Foot

Minimum Order Quantity : 160 Square Foots

Usage : Other, Building Cladding, Facades, Signage

Application : Exterior

Surface Treatment : PVDF Coated

Feature : Other, Fireproof, Lightweight, UV Resistant

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS